TRAME DI STORIA

- No products in the cart.

Subtotal

€0.00

Flax – vegetal fiber is a cellulosic plant fiber 1, the oldest used by man;

it is extracted from the stem of Linum Usatissum by macerating the fibrous bundles contained in the book2; it is extracted from the stem of the plant, which can reach a maximum height of 100cm..

Linen was known and appreciated in ancient Egypt (beautiful and precious finds are preserved in the Egyptian Museum of Turin and in that of Cairo);

it was also cultivated by the Babylonians and the Phoenicians, who were responsible for its diffusion among the Greeks and Romans, as an alternative to wool; in the Middle Ages flax found its main production center in Flanders, because of the humid climate of those areas, which favors its development.

Until the beginning of the nineteenth century, linen was the most used vegetable fiber by the middle-upper classes (while for thepoorest hemp was used, a fiber which is easier to cultivate and very rough both in appearance and to the touch);

later it was supplanted by cotton, which became more popular thanks to the introduction of improved looms, capable of weaving pure fiber in large quantities;

However, it had remained a very popular fiber to this day and still has relatively high cost.

Flax – vegetable fiber has a rather short cultivation cycle, it is sown in March and harvested in Augurst-September

There are two different tipe of cultivation, one is for fiber, the other is for seeds:

The first prefers cool weather, humid climates, with no big temperature variations; reaches a height of one meter;

The second, on the other hand, warm climates are more suitable and reaches modest heights

It has beautiful blue-white flowers of very short life.

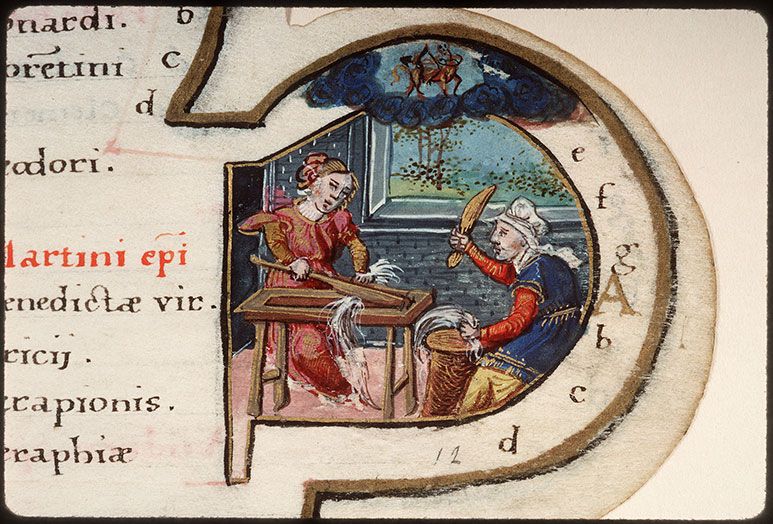

After harvesting (which today is dome with special combine harvester, but originally mowed by hand ), the plant is left to dry; subsequently it is soaked in water to collect fibers;

If you want to get seeds instead you pass to the beating;

After maceration by water soaking, we mode to kneading: it Isa process phase in which machines are used that separate the fiber from the woody part and divide the long fibers from short ones.

In the phase following he kneading, vegetable fiber of the flax passes to the grooming, in which the fiber is cleaned mor thoroughly, after which it passes to the combing, which aligns the fibers, so as to be able to proceeded with the spinning.

The long fibers, called long linden, are more valuable and destined for the productions of clothing and linen; the short ones, called linen tow, are used instead for the production of ropes and tow.

From the processing of the seeds we obtain the flour, used in cooking, and the oil which is widely used in the preparation of paints and in the treatment of wood; finally, a fiber called ramie is obtained from a chemical extractions process.

Spinning is done by twisting the long fibers, arranged in skeins that can be boiled, depending on the destinations of use, to soften the fiber.

Very thin or rough yarns are obtained from linen, depending on the type of fabric to be produced.

Today linen is dyed without any problem, thanks to very powerful chemical mordants3, which open the fibers and ensure they the pigment, also chemical origin, penetrates deeply and results in solid, intense and long-lasting colors;

In ancient times (and in natural dyeing ), linen presented various problems due to the difficulty of making the color penetrate into the fibers, which is why it was more often used in its natural state; the original color varies from ecru to off-white and in the Middle Ages it was mainly used for underwear.

The linen was dyed anyway with great effort, but the process to achieve solid and lasting colors was very long and required a huge skill from the dyer, for this reason only those who belonged to the wealthy and people who could afford it.

It consist in the final part of the flax cycle and depending on the thickness of the yarn it is possible to obtain very thin, precious an fresh muslin4, suitable for the fabrication of clothing and light curtains, or very thick, resistant and heavy fabrics, suitable for structured garments, heavy curtains and drapes in general.

In addition to being a very long-lasting material, it lends itself to being transformed into paper, thanks to the large amount of cellulose (about 70% ) found in the fiber.

Glossary :

1)Which contains a large amount of cellulose

2)Part immediately below the outermost part of the plant.

3)Chemical or natural products, which dissolve in the vin water where the fiber is boiled in the preparation phase of dyeing.

4)Very light and thin, semi transparent fabric.